High Fineness High Output Screening Mill Technology

Introduction

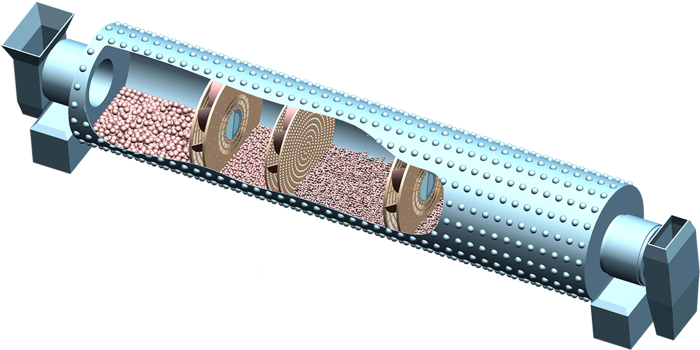

High fineness, high output screening mill technology is a technology improving grinding efficiency for the ball mill. The new screening partition plate with the function of separating is installed in the mill to reduce over-grinding condition. The micro grinding medium is used to increase grinding efficiency. The removable liners and flow speed control measures are taken to strength grinding operation. Thus it achieves the goal of output increasing and energy saving.

The technology obtained U.S. Invention Patent, China Invention Patent and 2nd award of Scientific and Technological Advancement at the State Level. It has been successfully applied to more than 1000 sets of mills, which has brought good economic and social benefits.

Characteristics

- It is applicable to all kinds of cement grinding system with an increase of output by 20~40% and with power saving by 17~30% while improving cement quality and performance.

- It is applicable to both open circuit and close circuit grinding processes.

- It is especially suitable for combined grinding system with the roller press.

- It is especially suitable for the grinding of slag fine powder, steel slag fine powder, super-fine fly ash with specific area up to 500~700m2/kg.

- It has been successfully applied to the grinding of iron oxide powder (average size ≤ 6μm), desulfated limestone (325-400 mesh)and superfine cementing materials(600~700m2/kg).

- It has such advantages as low investment, small time consumption and quick return in technological modification.